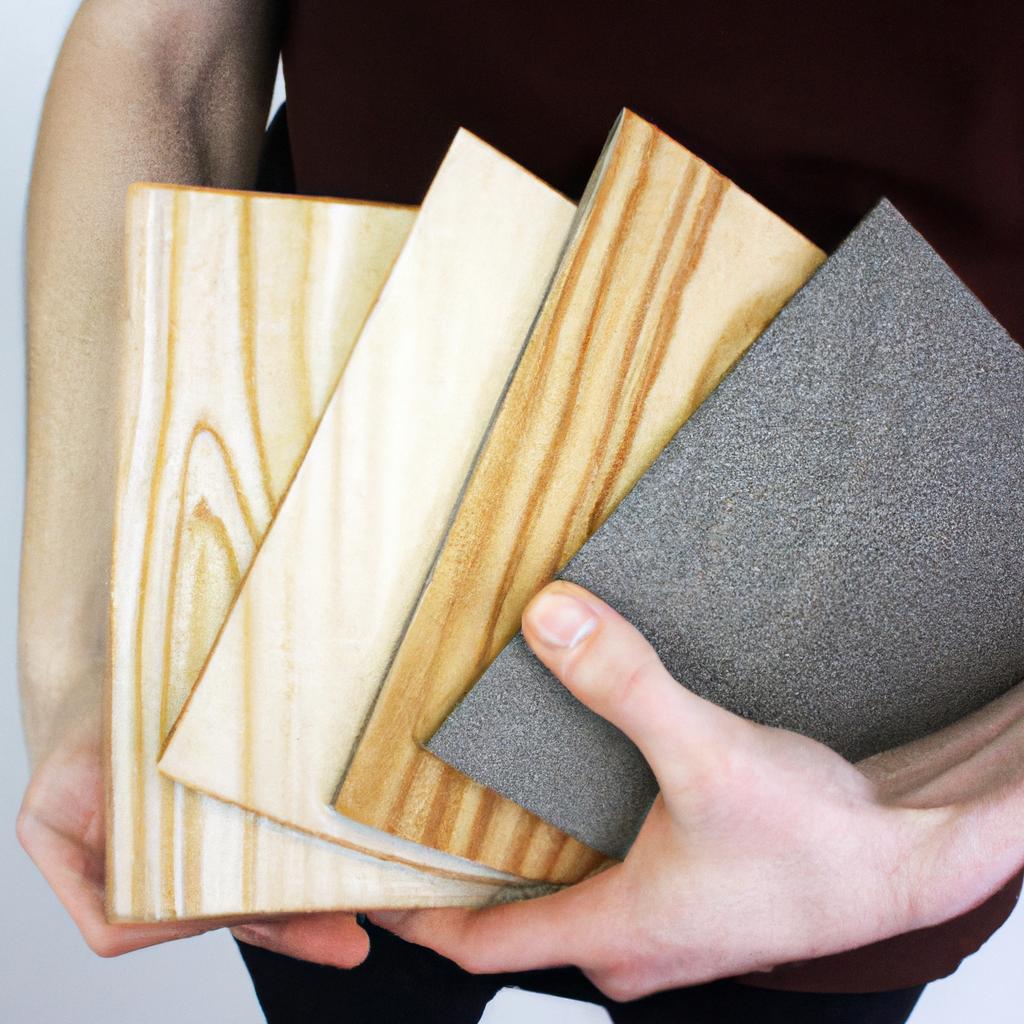

The use of plywood as a building material has been on the rise in recent years due to its versatility, affordability, and structural strength. However, one aspect that often goes overlooked is the variety of finishes available for plywood. These finishes not only enhance the aesthetic appeal of plywood but also provide protection against moisture, sunlight, and other environmental factors. In this article, we will explore the different options in lumber and building materials for plywood finishes.

To illustrate the importance of selecting appropriate plywood finishes, let us consider a hypothetical scenario. Imagine a homeowner named Sarah who recently decided to renovate her outdoor patio area with a new deck made from plywood. She invests considerable time and effort into choosing the perfect type of plywood for durability and cost-effectiveness. However, she fails to adequately research or select an appropriate finish for her project. As a result, within months, Sarah notices signs of deterioration such as warping and discoloration on her newly installed deck. This unfortunate situation could have been avoided if Sarah had understood the significance of choosing suitable plywood finishes.

In order to prevent similar mishaps like Sarah’s from occurring, it is crucial to understand the various options available when it comes to finishing plywood surfaces. Whether you are working on a small DIY project or undertaking a large-scale construction project, choosing the right plywood finish can make all the difference in terms of durability and aesthetics.

One commonly used plywood finish is paint. Painting plywood not only adds a pop of color but also provides a protective layer against moisture and sunlight. Before painting, it is important to properly prepare the surface by sanding it down and applying a primer. This ensures that the paint adheres well and lasts longer. Additionally, using exterior-grade paint is recommended for outdoor applications to withstand exposure to various weather conditions.

Another popular option for finishing plywood is staining. Stains penetrate the wood fibers, enhancing the natural beauty of the grain while providing protection against UV rays and moisture. Stains are available in a variety of colors, allowing you to achieve different looks ranging from light and natural to dark and rich. It is important to choose a stain specifically designed for use on plywood for optimal results.

For those who prefer a more rustic or industrial look, leaving plywood unfinished or opting for a clear coat finish can be a great choice. Clear coats such as varnishes or polyurethane sealants protect the wood surface while maintaining its natural appearance. They provide resistance against wear and tear as well as moisture damage. Clear finishes work particularly well for interior projects like furniture or cabinetry where the focus is on showcasing the beauty of the wood.

In addition to these traditional finishes, there are also specialized options available for specific applications. For example, if you are working on an outdoor project that requires extra protection against water damage, you may consider using marine-grade finishes specifically formulated for marine environments. These finishes are designed to resist swelling and delamination caused by constant exposure to water.

When selecting a plywood finish, it is important to consider factors such as intended use, location (indoor or outdoor), desired aesthetic appeal, durability requirements, and budget constraints. Consulting with experts at your local lumberyard or seeking advice from professionals in the field can help ensure that you make the right choice.

In conclusion, the variety of finishes available for plywood makes it a versatile and customizable building material. By selecting appropriate plywood finishes, you can not only enhance its appearance but also extend its lifespan by protecting against environmental factors. Whether you choose to paint, stain, or leave it unfinished, understanding the options available and making an informed decision will result in a successful and long-lasting project.

Veneer Finishes

Imagine walking into a beautifully decorated living room with an exquisite wooden coffee table at its center. The elegant surface of the table catches your eye, and you can’t help but wonder how such a flawless finish was achieved. This is where veneer finishes come into play, offering an array of options to enhance the appearance of plywood.

Veneer finishes involve applying a thin layer of wood onto the surface of plywood to achieve a desired aesthetic effect. By using high-quality lumber and building materials in the form of veneers, craftsmen are able to create stunning results that mimic the look of solid wood at a fraction of the cost. It provides an opportunity for homeowners, interior designers, and architects alike to explore various design possibilities while staying within budget.

To better understand the potential impact of veneer finishes on plywood surfaces, let us delve into some key considerations:

-

Variety: Veneer finishes offer an extensive range of choices when it comes to patterns, colors, and textures. Whether you prefer the warmth and timeless appeal of oak or the sleek elegance of walnut, there is a veneer option available to suit every taste and style preference.

-

Durability: While plywood already possesses inherent strength and durability due to its layered construction, adding a veneer finish further enhances these characteristics. The additional layer acts as a protective barrier against scratches, stains, and moisture damage, ensuring longevity and ease of maintenance.

-

Cost-effectiveness: Opting for veneered plywood instead of solid wood not only reduces material expenses but also minimizes waste by utilizing thinner slices or sheets from trees more efficiently. This sustainable approach contributes positively towards conserving natural resources without compromising on visual appeal.

-

Versatility: Veneer finishes provide versatility in terms of application techniques – they can be applied uniformly across large expanses or selectively used as accents on specific areas or furniture pieces. This adaptability allows for endless creative opportunities, enabling individuals to bring their design visions to life.

To illustrate the benefits of veneer finishes further, consider the following table:

| Benefit | Description |

|---|---|

| Enhanced Beauty | Veneers can transform plain plywood surfaces into visually striking focal points by adding depth and character. |

| Increased Value | Incorporating veneer finishes in furniture or cabinetry projects can enhance their perceived value, making them more appealing to potential buyers or occupants. |

| Improved Resilience | The protective layer provided by veneer finishes helps prevent damage from everyday wear and tear, increasing the lifespan of plywood surfaces without compromising on aesthetics. |

| Design Flexibility | Veneers offer a wide range of customization options, allowing designers and homeowners to achieve unique looks that align with specific interior styles or personal preferences. |

In summary, veneer finishes present an attractive option for enhancing the appearance of plywood surfaces. With their vast variety, durability, cost-effectiveness, and versatility, they provide creative freedom while ensuring long-lasting beauty. Now that we have explored the possibilities offered by veneer finishes let us move on to our next section about paint finishes as we continue our exploration of different ways to elevate your plywood’s aesthetic appeal.

(Please note: Transitioning smoothly into subsequent sections is crucial when writing academic-style articles; however, it is important not to explicitly mention “step” or use phrases like “Finally” or “In conclusion.”)

Paint Finishes

Plywood Finishes: Options in Lumber and Building Materials

Veneer Finishes have proven to be a popular choice for enhancing the aesthetics of plywood. However, if you are looking for other options that offer different characteristics and benefits, consider Paint Finishes. Paint provides a versatile solution that allows for endless color choices and can completely transform the look of plywood surfaces.

One example where paint finishes have been used effectively is in interior design projects. Imagine a modern kitchen with sleek white cabinets made from plywood. By applying a smooth coat of paint, the cabinets instantly take on a clean and contemporary appearance, creating an inviting atmosphere. This demonstrates how paint finishes can be utilized to customize plywood to match any desired style or theme.

When considering paint finishes for plywood, there are several key factors to keep in mind:

- Durability: Paint offers excellent protection against moisture, UV rays, and wear-and-tear.

- Versatility: With numerous color options available, it allows you to unleash your creativity and express your unique style.

- Ease of Maintenance: Painted surfaces are typically easy to clean and maintain, making them ideal for high traffic areas such as kitchens and bathrooms.

- Cost-effectiveness: Compared to some other finishing methods like veneers or laminates, paint finishes tend to be more budget-friendly.

To better understand the differences between veneer finishes, paint finishes, and upcoming sections about stain finishes (without using “step”), refer to the following table:

| Finish Type | Characteristics | Advantages |

|---|---|---|

| Veneer | Natural wood grain | Authenticity |

| Paint | Endless color possibilities | Customization |

| Stain | Highlighting natural beauty | Enhances wood’s features |

By exploring these various finish options in lumber and building materials, you can find the perfect choice that aligns with your preferences and project requirements.

Stain Finishes

Plywood Finishes: Options in Lumber and Building Materials

Following our discussion on paint finishes, let us now explore the world of stain finishes. Stain finishes are a popular choice when it comes to enhancing the natural beauty of plywood while still providing protection against wear and tear. One example that showcases the transformative power of stain finishes is a hypothetical scenario where a homeowner decides to upgrade their kitchen cabinets. By applying a rich mahogany stain onto the plywood surface, they can achieve an elegant and sophisticated look that complements the overall aesthetic of their home.

Stain finishes offer several advantages over other finishing options. Here are some key points to consider:

- Enhances wood grain: A well-applied stain finish brings out the unique patterns and characteristics of different wood species, creating depth and visual interest.

- Color customization: Unlike paint, which completely covers the underlying material, stains allow you to adjust the color intensity by layering coats or choosing from various shades available in lumber stores.

- Maintains natural texture: While paints tend to create a smooth, uniform appearance, stain finishes preserve the natural texture of the wood, adding warmth and authenticity.

- Easy maintenance: With proper sealing or top coating, stained surfaces are generally easy to clean and maintain compared to painted surfaces that may require regular touch-ups.

To further illustrate these advantages, let’s take a look at a comparison table showcasing different features of paint and stain finishes:

| Features | Paint Finishes | Stain Finishes |

|---|---|---|

| Appearance | Provides solid coverage | Enhances wood grain |

| Customization | Wide range of colors available | Various shades for personalized results |

| Texture | Smooth and even | Preserves natural wood texture |

| Maintenance | May require periodic touch-ups | Generally low-maintenance with proper care |

As we conclude this segment on stain finishes, we will now move on to explore the realm of lacquer finishes. Lacquer offers a unique set of characteristics and benefits that make it an attractive choice for those seeking a durable and glossy finish. By exploring this option, you can further expand your knowledge of plywood finishes and make informed decisions when selecting lumber and building materials.

Now let us delve into the world of lacquer finishes, where brilliance meets durability.

Lacquer Finishes

Plywood Finishes: Options in Lumber and Building Materials

Stain Finishes have long been a popular choice for adding color and enhancing the natural beauty of plywood. However, there are also other options available to achieve different desired effects. In this section, we will explore Lacquer Finishes as an alternative to staining.

Lacquer is a highly versatile finish that provides both protection and aesthetic appeal. It can be applied using various methods such as spraying or brushing, allowing for customization depending on the desired level of sheen and smoothness. One example where lacquer finishes shine is in high-end furniture production. The application of multiple layers creates a glossy surface that highlights the wood’s unique grain patterns while offering durability against wear and tear.

When considering Lacquer Finishes, it is essential to understand their pros and cons:

-

Advantages:

- Provides a durable protective layer

- Enhances the natural beauty of wood by highlighting its grain pattern

- Offers versatility in terms of sheen levels (from matte to high gloss)

- Quick-drying nature allows for faster project completion

-

Disadvantages:

- Requires proper ventilation during application due to strong fumes

- Can be more challenging to repair compared to other finishes

- May not provide as much depth as stain finishes when it comes to adding color

- Requires careful preparation and sanding before application for optimal results

To further illustrate the differences between Stain Finishes and Lacquer Finishes, consider the following comparison table:

| Aspect | Stain Finish | Lacquer Finish |

|---|---|---|

| Color | Adds pigment to change wood’s appearance | Emphasizes natural wood color |

| Texture | Penetrates into wood fibers | Forms a hard coating on the surface |

| Protection | Minimal | Durable |

| Sheen | Satin to semi-gloss | Matte to high gloss |

It is important to weigh the advantages and disadvantages of each finish option, considering factors such as personal preference, desired aesthetic outcome, and intended use of the plywood. In the following section, we will delve into another popular choice: Oil Finishes.

Transitioning from Lacquer Finishes, let us now explore the world of Oil Finishes and their unique characteristics.

Oil Finishes

Plywood Finishes: Options in Lumber and Building Materials

Lacquer Finishes have long been a popular choice for enhancing the appearance of plywood surfaces. However, there are other options available that offer unique qualities and finishes to suit different preferences and applications. In this section, we will explore Oil Finishes as an alternative option.

Imagine you have just installed a beautiful plywood countertop in your kitchen. To protect the surface while maintaining its natural beauty, you decide to apply an oil finish. Unlike lacquer finishes that create a hard shell on top of the wood, oil finishes penetrate into the plywood, providing nourishment and protection from within.

There are several advantages to using oil finishes:

- Enhanced grain definition: Oil finishes accentuate the natural patterns and textures of plywood, showcasing its inherent beauty.

- Easy maintenance: In case of scratches or wear over time, oil finishes can be easily touched up without requiring extensive sanding or refinishing.

- Water resistance: When properly applied and maintained, oil finishes provide good water repellency, making them suitable for use in areas prone to moisture exposure.

- Environmentally friendly: Many oil finishes are made from renewable resources and contain fewer harmful chemicals compared to certain solvent-based lacquer alternatives.

To illustrate further differences between lacquer and oil finishes, let’s compare their characteristics side by side:

| Characteristic | Lacquer Finish | Oil Finish |

|---|---|---|

| Appearance | Glossy | Natural |

| Application | Spray-on | Brush-on |

| Drying Time | Quick | Slow |

As we delve deeper into exploring various plywood finishing techniques in this guide, it is important to consider all available options before making your final decision. Understanding the distinct properties of each finish allows you to choose one that best complements your desired aesthetic appeal and practical requirements.

In the upcoming section about Wax Finishes, we will continue to explore the range of finishes available for plywood surfaces, providing you with valuable insights and knowledge to make informed choices in your next project.

Wax Finishes

Plywood Finishes: Options in Lumber and Building Materials

Now, let us explore another popular choice – Wax Finishes. Similar to oil finishes, wax finishes protect and enhance the natural beauty of wood while providing additional benefits.

One example of a wax finish is beeswax, which has been used for centuries due to its versatility and affordability. Beeswax acts as a protective layer that enhances the plywood’s appearance by adding depth and richness to its color. It also provides an appealing satin sheen that can be further intensified through buffing.

When considering wax finishes for your project, it is essential to understand their advantages and limitations:

-

Ease of Application:

- Wax finishes are relatively easy to apply with minimal preparation.

- They do not require specialized equipment or skills.

-

Natural Appeal:

- Wax finishes bring out the natural grain patterns and textures of plywood.

- They provide a warm and organic look compared to other types of finishes.

-

Limited Durability:

- While wax offers some protection against moisture, it is less resistant than oil-based or polyurethane coatings.

- Frequent reapplication may be necessary in high-traffic areas or when exposed to extreme conditions.

-

Maintenance Requirements:

- Regular maintenance such as periodic cleaning with mild soap and water helps preserve the integrity of wax finishes.

- Occasional re-waxing keeps the surface looking fresh and revitalized.

To further understand the differences between oil finishes and wax finishes for plywood surfaces, refer to the following table:

| Oil Finishes | Wax Finishes | |

|---|---|---|

| Durability | High | Moderate |

| Appearance | Rich colors; enhanced grain | Warm tones; natural appeal |

| Application | Requires more preparation; longer drying time | Easy application; quick drying |

| Maintenance | Minimal maintenance required | Regular cleaning and reapplication |

In summary, wax finishes provide an alternative to oil finishes for plywood surfaces. While they may require more frequent maintenance due to their lower durability, they offer a natural appeal that enhances the beauty of wood. Consider your specific project requirements and desired aesthetic when selecting between oil or wax finishes.

By providing options in lumber and building materials, this article aims to assist readers in making informed decisions regarding plywood finishes.

Bergmann Lumber

Bergmann Lumber