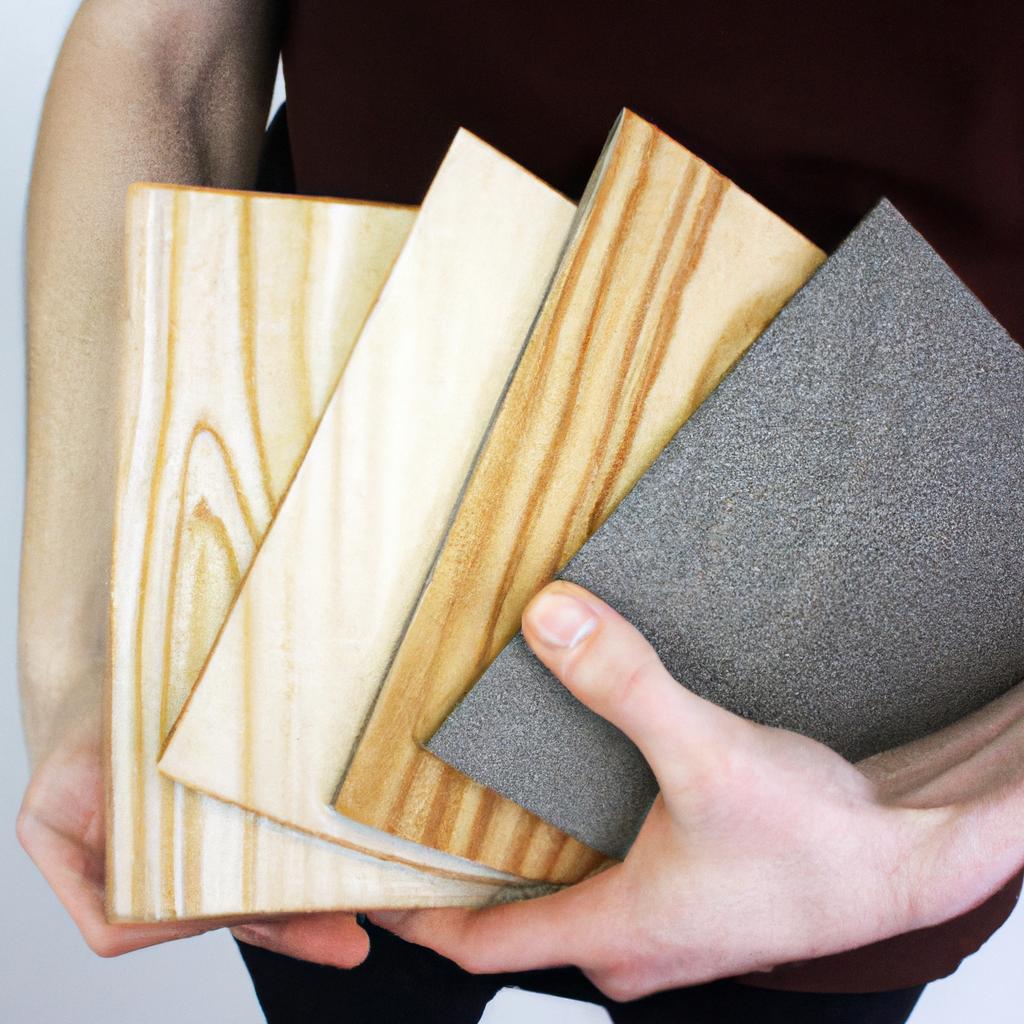

Plywood is a versatile building material widely used in the construction industry for various applications such as flooring, roofing, and wall sheathing. However, selecting the appropriate plywood thickness can be challenging due to the plethora of options available in the market. For instance, imagine a scenario where an individual aims to install new subflooring in their home but is uncertain about which plywood thickness would best suit their needs. This article seeks to provide an informative guide on plywood thicknesses in lumber and building materials, aiming to assist individuals in making informed decisions regarding this critical aspect of construction.

Understanding the significance of plywood thicknesses is essential for ensuring structural integrity and durability in construction projects. Plywood typically comes in varying thicknesses ranging from 1/8 inch (3 mm) up to 1-1/4 inches (32 mm). Each thickness option serves different purposes depending on the specific requirements of the project at hand. By exploring factors such as load-bearing capacity, intended use, and spanning capabilities, one can make well-informed choices when it comes to selecting the most suitable plywood thickness for a particular application. This comprehensive guide will delve into these considerations while shedding light on common practices within the industry and offering practical recommendations for optimal results.

Understanding Plywood Thickness Standards

Imagine you are a homeowner looking to build a new deck in your backyard. You visit the local lumberyard and find yourself surrounded by stacks of plywood sheets of varying thicknesses. Confusion sets in as you try to decipher which one is suitable for your project. This scenario highlights the importance of understanding plywood thickness standards, as it ensures that you select the appropriate material for your construction needs.

To comprehend plywood thickness standards effectively, it is crucial to first acknowledge their purpose. These standards serve as guidelines set forth by industry organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). By adhering to these guidelines, manufacturers can produce consistent plywood products that meet specific requirements related to strength, durability, and compatibility with various applications.

One way in which plywood thickness standards are established is through numerical measurements. For instance, a common standard may dictate that a particular type of plywood should have a minimum thickness measurement of 1/4 inch or 0.635 centimeters. However, it is essential to note that these measurements can vary depending on regional preferences and building codes.

Understanding this variability brings us to an emotional realization: navigating the world of plywood thicknesses can be daunting for even experienced builders. To simplify matters, here is a bullet point list summarizing key aspects of plywood thickness standards:

- Different types of projects require different plywood thicknesses.

- Thicker plywood generally offers increased strength but at higher costs.

- Factors such as load-bearing requirements and environmental conditions influence the choice of plywood thickness.

- Consulting professionals or referring to building codes can help determine appropriate choices.

Furthermore, visual aids such as tables provide an additional layer of clarity when discussing plywood thickness standards. The table below demonstrates how different types of construction projects often correspond with recommended ranges of plywood thickness:

| Construction Project | Recommended Plywood Thickness Range |

|---|---|

| Subflooring | 3/4 – 1 inch (1.905 – 2.54 cm) |

| Roof Sheathing | 1/2 – 5/8 inch (1.27 – 1.5875 cm) |

| Wall Sheathing | 7/16 – 11/32 inch (1.11125 – 0.87375 cm) |

| Furniture and Cabinetry | Varies depending on specific needs |

In conclusion, understanding plywood thickness standards is essential for selecting the appropriate material for your construction projects. By following industry guidelines and considering factors such as project requirements, load-bearing capacity, and environmental conditions, you can make informed decisions about plywood thicknesses.

Next, we will explore common plywood thicknesses for construction projects to provide further insight into this topic and guide you in making well-informed choices without feeling overwhelmed by the numerous options available.

Common Plywood Thicknesses for Construction Projects

When it comes to selecting the right plywood for your construction projects, understanding the various thickness standards is essential. Let’s take a closer look at some common plywood thicknesses used in building materials and how they can impact your project.

Imagine you are planning to build a bookshelf using plywood as the main material. In this case, you would need to consider the weight-bearing capacity of the shelves and ensure that the plywood chosen is thick enough to support books of different sizes and weights. This example highlights the importance of selecting an appropriate thickness that aligns with your specific project requirements.

To assist you further, here are four key considerations when choosing plywood thickness:

- Strength Requirements: Determine the load-bearing capacity needed for your project.

- Application: Consider where and how the plywood will be used (e.g., flooring, roofing, or wall sheathing).

- Cost Efficiency: Balance between cost and performance by evaluating if thicker plywood provides added benefits compared to thinner options.

- Structural Integrity: Ensure that the selected thickness maintains structural integrity throughout its intended lifespan.

Now let’s delve into a table outlining some commonly available standard plywood thicknesses found in lumberyards or home improvement stores:

| Thickness (inches) | Common Uses | Pros |

|---|---|---|

| 1/4″ | Cabinet backing | Lightweight |

| 3/8″ | Furniture panels | Versatile |

| 1/2″ | Shelving systems | Good balance of strength |

| 3/4″ | Subflooring, roof decking | Sturdy |

In conclusion, understanding plywood thickness standards plays a crucial role in ensuring successful outcomes for your construction projects. By considering factors such as strength requirements, application needs, cost efficiency, and structural integrity, you can make informed decisions about which thickness of plywood best suits your specific project goals. Next, we will explore how to choose the right plywood thickness for your project, building upon the knowledge gained in this section.

Transitioning into the subsequent section about “Choosing the Right Plywood Thickness for Your Project,” let’s now discuss some practical steps that can help you make an informed decision.

Choosing the Right Plywood Thickness for Your Project

When embarking on a construction project, it is crucial to select the appropriate plywood thickness that can withstand the structural demands. To illustrate this point, let’s consider a hypothetical scenario where an individual plans to build a sturdy outdoor shed in their backyard. In such a case, using plywood with insufficient thickness could compromise the shed’s durability and potentially lead to costly repairs or even collapse.

To ensure optimal performance and longevity of your construction project, here are some key considerations when choosing the right plywood thickness:

-

Load-bearing capacity: Different projects require varying levels of strength and support. For instance, if you intend to construct a heavy-duty storage shelf capable of holding significant weight, opting for thicker plywood will enhance its load-bearing capacity.

-

Span length: The distance between supports also influences the choice of plywood thickness. Longer spans necessitate thicker sheets to prevent sagging or bending under pressure.

-

Environmental factors: Outdoor applications expose plywood to elements like moisture, temperature fluctuations, and UV radiation. Thicker plywood provides better protection against these environmental factors and increases resistance to rotting and warping.

-

Desired finish: If you plan on painting or staining your project, thinner plywood may be more suitable as it allows for smoother finishes due to its reduced surface imperfections.

Consider the following table showcasing common applications and recommended thicknesses based on industry standards:

| Application | Recommended Thickness |

|---|---|

| Subflooring | 23/32″ (18mm) |

| Roof Sheathing | 15/32″ (12mm) |

| Wall Sheathing | 7/16″ (11mm) |

| Cabinet Backs | 1/4″ (6mm) |

In summary, selecting the correct plywood thickness is essential in ensuring structural integrity and long-term stability for your construction projects. By considering factors such as load-bearing capacity, span length, environmental conditions, and desired finish, you can make informed decisions that will contribute to the success of your project.

Transitioning into the subsequent section on exploring specialty plywood thicknesses for specific applications, it is important to delve deeper into understanding how different projects may require unique considerations when selecting plywood thickness.

Exploring Specialty Plywood Thicknesses for Specific Applications

Transitioning from the previous section, let us now delve into the realm of specialty plywood thicknesses that cater to specific applications. To better understand how this can impact your project, consider the following example:

Imagine you are an architect designing a custom-built kitchen cabinet set. The client desires a sleek and modern aesthetic while ensuring durability and structural integrity. In order to meet these requirements, you must carefully select plywood with appropriate thickness.

When it comes to specialty applications, there are several factors to keep in mind when choosing plywood thickness:

- Weight-bearing capacity: Consider the weight that will be placed on the surface made from plywood. Thicker plywood sheets tend to have higher load-carrying capacities, making them suitable for heavy-duty applications such as underlayment or flooring in high-traffic areas.

- Stability and resistance: If your project requires stability against warping or moisture damage, thicker plywood is often preferred due to its increased resistance to bending and greater dimensional stability.

- Acoustic properties: Thicker plywood panels generally provide better sound insulation than thinner ones, which makes them ideal for projects involving music studios or soundproofing rooms.

- Cost implications: While thicker plywood may offer added benefits in terms of strength and performance, it is important to weigh these advantages against budgetary constraints.

To illustrate further, here is a table highlighting different common specialty applications along with their recommended plywood thicknesses:

| Application | Recommended Plywood Thickness |

|---|---|

| Cabinetry | 1/4″ – 3/4″ |

| Flooring | 5/8″ – 1 1/4″ |

| Soundproofing | 3/4″ – 1 1/2″ |

| Structural Support | 1″ – 2″ |

As you can see, the appropriate plywood thickness varies depending on the intended use and desired performance of the project. Considering these factors will help ensure that your choice aligns with both functional requirements and budget constraints.

Transitioning to the next section about “Factors to Consider When Selecting Plywood Thickness,” let us now explore key considerations in determining the right plywood thickness for your specific needs. By taking into account various aspects related to your project, such as load-bearing requirements and environmental conditions, you can make an informed decision that optimizes both functionality and cost-effectiveness.

Factors to Consider When Selecting Plywood Thickness

In the previous section, we delved into the various standard thicknesses of plywood used in general construction and carpentry. Now, let us turn our attention to specialty plywood thicknesses that cater to specific applications. To illustrate this further, consider a hypothetical scenario where an interior designer is tasked with creating a custom-built bookshelf utilizing plywood.

When designing a bookshelf, it is crucial to select the appropriate plywood thickness based on factors such as load-bearing capacity and aesthetics. Here are some key considerations:

- Strength: The weight of books can exert significant pressure on a bookshelf’s shelves. Choosing thicker plywood with enhanced structural integrity will ensure durability and prevent sagging over time.

- Visual appeal: While functionality remains paramount, understandably, appearances matter too. By opting for thinner plywood veneers backed by stronger cores or using multiple layers of thin sheets laminated together, designers can achieve visually pleasing results without compromising strength.

- Flexibility: If you anticipate rearranging your bookshelf frequently or plan to use adjustable shelving systems, selecting thinner plywoods may provide more flexibility in terms of customization and ease of modification.

- Budget constraints: Specialty plywood often comes at a higher cost compared to standard options due to its unique properties and manufacturing processes involved—balancing functional requirements while staying within budget limits becomes vital.

| Application | Recommended Plywood Thickness |

|---|---|

| Lightweight furniture | 6 – 9 mm |

| Cabinet doors | 12 – 18 mm |

| Flooring | 16 – 20 mm |

| Stair treads | ≥25 mm |

As seen from the table above, each application requires varying levels of strength and stability. By carefully selecting the appropriate plywood thickness, you can ensure that your project meets both functional and aesthetic requirements.

In the subsequent section, we will discuss essential tips for properly measuring and cutting plywood. Understanding these guidelines will help you achieve accurate dimensions for your woodworking projects without any unnecessary waste or errors in construction. So let’s delve into this topic further to enhance your carpentry skills.

Tips for Properly Measuring and Cutting Plywood

In the previous section, we discussed various factors that should be taken into consideration when selecting plywood thickness. Now, let’s delve deeper into these factors and explore their implications for your lumber and building materials projects.

One important factor to consider is the intended use of the plywood. For instance, if you are planning to use it for flooring or roofing purposes, a thicker plywood would be more suitable as it provides increased strength and durability. On the other hand, if you need plywood for interior paneling or furniture construction, a thinner option may suffice without compromising on quality.

Another crucial aspect to keep in mind is the span between supports. The distance between structural supports will influence the load-bearing capabilities of the plywood. A wider span generally requires a thicker plywood to ensure optimal support and prevent sagging or bending over time.

Climate conditions also play a significant role in determining the appropriate plywood thickness. In regions with extreme weather patterns or high humidity levels, opting for thicker plywood can enhance its resistance against warping or moisture damage. Conversely, in areas with milder climates, thinner options might be sufficient while still meeting necessary requirements.

To further illustrate these considerations, let’s imagine a hypothetical scenario where you are constructing a shed using plywood for both the walls and roof. Taking into account our aforementioned factors—intended use, span between supports, and climate—you decide on 1/2-inch thick plywood for the walls due to insulation needs but opt for 3/4-inch thick plywood for added structural integrity in order to support heavy snow loads during winter months.

Considerations when selecting plywood thickness include:

- Intended use: Determine if it will be used for flooring, roofing, paneling, or furniture.

- Span between supports: Evaluate the distance between structural supports to ensure proper load-bearing capacity.

- Climate conditions: Take into account regional weather patterns and humidity levels that may affect plywoods’ performance.

- Aesthetics: Choose plywood thickness that aligns with the desired visual appeal and design.

Table: Plywood Thickness Recommendations

| Intended Use | Recommended Thickness |

|---|---|

| Flooring | 3/4 inch |

| Roofing | 1/2 to 5/8 inch |

| Paneling | 1/4 to 1/2 inch |

| Furniture | 1/4 to 3/4 inch |

By considering these factors, you can confidently select the appropriate plywood thickness for your specific project requirements. Remember, ensuring adequate strength and durability will contribute to the long-term success of your construction endeavors without compromising on quality or safety.

Bergmann Lumber

Bergmann Lumber