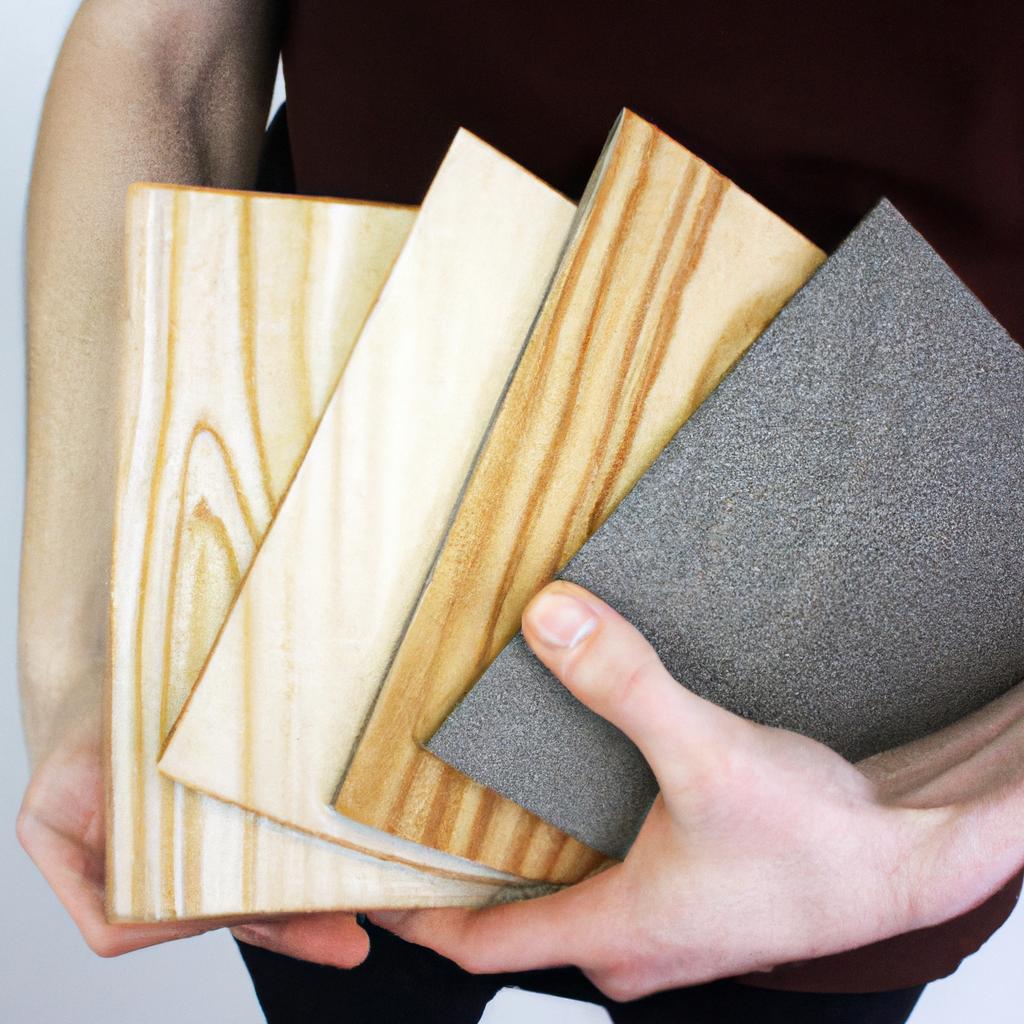

Plywood is a versatile and widely used building material in the construction industry. It offers immense strength, durability, and flexibility, making it an essential component in various applications such as flooring, roofing, siding, and furniture manufacturing. However, one crucial aspect that often goes overlooked is understanding the different sizes of plywood available in the market. Imagine a scenario where a homeowner embarks on a DIY project to build their own backyard shed. They meticulously plan out every detail but overlook the importance of choosing the right size of plywood for their project. This oversight could lead to unnecessary wastage of materials or even compromise the structural integrity of the shed. Therefore, having knowledge about plywood sizes becomes paramount for anyone involved in lumber and building materials.

In order to make informed decisions regarding plywood selection, it is imperative to grasp fundamental information about plywood sizes. Plywood comes in standard dimensions that are commonly referred to by thickness and length-width ratios. The most frequently encountered thicknesses include 3/4 inch, 1/2 inch, and 1/4 inch, while common lengths range from 8 feet to 10 feet. Understanding these measurements allows builders and homeowners alike to accurately estimate material requirements for their projects and avoid costly mistakes caused by improper sizing choices. Furthermore , knowing the standard sizes of plywood also helps in determining the appropriate spacing for supporting structures and ensuring proper installation.

In addition to the standard sizes, plywood can also be custom cut to fit specific project requirements. This flexibility allows for greater customization and precision in construction projects. However, it is important to note that custom cutting may incur additional costs and should be carefully planned to minimize wastage.

To ensure a successful DIY project using plywood, it is recommended to carefully measure and plan out the dimensions required for each component. This includes accurately calculating the surface area that needs to be covered and factoring in any necessary allowances for overlapping or joining pieces together.

It is also worth mentioning that plywood sizes may vary slightly between different manufacturers or regions. Therefore, it is advisable to consult with local suppliers or refer to their product specifications to obtain accurate information on available sizes.

Overall, understanding plywood sizes is crucial for anyone involved in construction projects as it allows for efficient material planning, cost-effective decision-making, and ultimately ensures a sturdy and well-built structure.

Understanding Plywood Grading

Imagine you are a homeowner looking to build a new bookshelf. You head to the local lumberyard and find yourself surrounded by stacks of plywood, each labeled with different grades. How do you know which one is right for your project? Understanding plywood grading can help you make an informed decision.

Plywood grading is a standardized system that assesses the quality and appearance of plywood panels. It ensures consistency in terms of structural integrity, surface finish, and overall suitability for various applications. One example of how grading affects product selection is demonstrated through the case study of two homeowners: Mr. Smith and Ms. Johnson. Both individuals required plywood sheets for their kitchen cabinets. While Mr. Smith opted for a lower-grade panel due to budget constraints, Ms. Johnson chose a higher-grade option to achieve a more refined look.

To better comprehend plywood grading, consider these key factors:

- Strength: Higher grade plywood tends to have fewer voids and defects, making it stronger and more durable.

- Surface Appearance: Grades range from A (best) to D (worst), with variations within each grade denoted by additional letters like A-C or B-B. Grade A offers a smooth, knot-free surface suitable for staining or painting, while Grade D may exhibit rough patches and visible knots.

- Application Suitability: Different grades are designed for specific purposes such as construction, furniture-making, or decorative finishes.

- Cost: As expected, higher-grade plywood typically comes at a premium price compared to lower-grade options.

By understanding these aspects of plywood grading, consumers can confidently select the appropriate panel based on their project requirements and budgetary considerations.

| Strength | Surface Appearance | Application Suitability | |

|---|---|---|---|

| Grade A | High | Smooth & Knot-Free | Furniture-Making |

| Grade B | Medium | Some Surface Defects | Construction, Cabinetry |

| Grade C | Low | Rough & Visible Knots | Structural Applications |

| Grade D | Lowest | Rough & Visible Knots | Temporary Use or Hidden Areas |

As you can see from the table above, each grade of plywood offers different strengths and surface appearances that align with specific applications. This information serves as a helpful guide in making an informed decision when selecting plywood for your next project.

Moving forward into the subsequent section about “Common Plywood Sizes and Dimensions,” we will explore the various sizes available and how they contribute to the overall versatility of plywood as a building material.

Common Plywood Sizes and Dimensions

From understanding the grading system of plywood, let’s now explore common plywood sizes and dimensions that are commonly used in various construction projects. To illustrate this, let’s consider a hypothetical scenario where a homeowner is planning to build a small shed in their backyard. They have decided to use plywood for the walls and roof of the shed.

When it comes to selecting plywood sizes, there are several factors that need to be taken into account. These include the specific requirements of the project, such as load-bearing capacity and structural stability. Additionally, considering the cost-effectiveness and availability of different sizes can help make an informed decision.

Here are some commonly available plywood sizes:

- 4 feet by 8 feet: This is one of the most widely used standard plywood sizes. It is versatile and easily accessible, making it suitable for a variety of applications.

- 2 feet by 4 feet: Also known as “project panels,” these smaller-sized sheets are often preferred for DIY or smaller-scale projects due to ease of handling and transportation.

- 5 feet by 5 feet: Commonly referred to as “baltic birch” plywood, these square-shaped sheets offer increased stability and durability compared to other varieties.

- Oversized sheets: Some manufacturers also produce larger-sized plywood sheets, typically measuring up to 5 feet by 10 feet. These oversized sheets minimize wastage during cutting and are ideal for large-scale projects.

To further understand how different plywood sizes correspond with their application potential, refer to the following table:

| Plywood Size | Recommended Use |

|---|---|

| 4′ x 8′ | General purpose applications |

| 2′ x 4′ | Small scale projects |

| 5′ x 5′ | Cabinet-making or furniture building |

| Oversized | Large construction projects |

By carefully considering these common plywood sizes and their recommended uses, our hypothetical homeowner can make an informed decision on the most suitable option for their shed project. Now that we have explored plywood sizes and dimensions, let’s delve into different types of plywood to further enhance our understanding.

Moving forward, it is essential to explore the different types of plywood available in the market to determine which one best suits specific construction needs.

Different Types of Plywood

Title: Plywood Sizes: Essential Information for Lumber and Building Materials

Previous section H2: Common Plywood Sizes and Dimensions

In the previous section, we explored the various common plywood sizes and dimensions available in the market. Now, let’s delve deeper into understanding the different types of plywood that are commonly used in construction projects.

Section: Different Types of Plywood

To illustrate the significance of choosing the right type of plywood, consider a hypothetical scenario where two builders are constructing houses using different types of plywood. Builder A opts for exterior grade plywood, while Builder B decides to use marine grade plywood. As time passes, both homes face severe weather conditions including heavy rainfall and high humidity levels. While Builder A’s house starts showing signs of water damage with warped panels and delamination issues, Builder B’s property remains unscathed due to the superior moisture resistance properties offered by marine grade plywood.

When selecting plywood for your project, it is important to consider not only its size but also its specific characteristics. Here are some key factors to keep in mind:

- Moisture Resistance: Some types of plywood offer enhanced moisture resistance properties, making them suitable for applications exposed to humid or wet environments.

- Strength and Durability: The strength of plywood can vary depending on its intended use. Consider whether you require standard structural strength or a higher level for specialized purposes.

- Appearance: Depending on your aesthetic preferences, certain types of plywood may have more visually appealing wood grains or finishes.

- Cost: Take into account your budget constraints as well as any trade-offs between price and performance when making your selection.

| Type | Description | Best Use |

|---|---|---|

| Exterior Grade | Resistant to moisture & suitable for outdoor use | Construction, roofing, sheathing |

| Marine Grade | Highly water-resistant & ideal for marine use | Boat building, docks, outdoor furniture |

| Hardwood Plywood | Made from hardwood veneers | Cabinetry, fine woodworking |

| Softwood Plywood | Made from softwood veneers | Subflooring, interior wall and ceiling applications |

In summary, choosing the appropriate type of plywood is crucial to ensure optimal performance and longevity of your construction projects. By considering factors such as moisture resistance, strength, appearance, and cost, you can make an informed decision that aligns with your specific requirements.

Next section H2: Factors to Consider When Choosing Plywood Sizes

Moving forward into our discussion on selecting plywood sizes for your project…

Factors to Consider When Choosing Plywood Sizes

Plywood Sizes: Essential Information for Lumber and Building Materials

Different Types of Plywood provide a range of options for various construction projects. However, once you have determined the type of plywood that suits your needs, another important consideration is choosing the right sizes. Selecting the appropriate plywood size ensures efficiency in material usage and minimizes wastage or unnecessary costs. Understanding the factors to consider when determining plywood sizes will help you make informed decisions.

To illustrate this point, let’s consider a case study involving a contractor tasked with building cabinets for a kitchen renovation project. The contractor initially plans to use 4′ x 8′ sheets of plywood but realizes that they may result in significant waste due to excess material after cutting pieces to fit specific cabinet dimensions. This realization prompts the contractor to explore alternative plywood sizes that can maximize material utilization while still meeting project requirements.

When deciding on plywood sizes, keep in mind the following factors:

- Project specifications: Consider the specific measurements required for each component or section of your project.

- Material availability: Check if the desired plywood size is readily available from suppliers or if custom orders are necessary.

- Handling capabilities: Assess whether larger sheet sizes present challenges in terms of transportation, maneuverability, and storage at your job site.

- Cost considerations: Evaluate how different plywood sizes affect overall project expenses by factoring in both material cost and potential wastage.

To further understand these considerations, refer to the table below showcasing different common plywood sizes along with their pros and cons:

| Size (in feet) | Pros | Cons |

|---|---|---|

| 4′ x 8′ | Widely available | Potential wastage |

| 2′ x 4′ | Easy handling | Limited availability |

| 5′ x 5′ | Reduced cuts | Higher cost per square foot |

| Custom | Tailored to project needs | Longer lead time |

By carefully evaluating the factors mentioned above, you can determine which plywood size will best suit your project requirements. The chosen size should strike a balance between efficient material usage and practicality during construction.

Moving forward, let’s explore the benefits of using standard plywood sizes in order to understand how they contribute to successful construction projects.

Benefits of Using Standard Plywood Sizes

Having discussed the factors to consider when choosing plywood sizes, it is important now to explore the benefits that come with using standard plywood sizes. By understanding these advantages, builders and homeowners can make informed decisions regarding their construction projects.

Benefits of Using Standard Plywood Sizes:

One example that illustrates the benefits of using standard plywood sizes involves a homeowner named Sarah who was renovating her kitchen cabinets. She initially considered custom-sized plywood panels to fit into each cabinet perfectly. However, after consulting with an experienced contractor, she learned about the advantages of utilizing standard sized plywood sheets instead. This not only saved her time but also reduced costs significantly.

The following bullet point list highlights some key emotional benefits associated with using standard plywood sizes:

- Consistency in availability ensures ease of sourcing materials.

- Reduced waste during construction contributes to environmental sustainability.

- Simplified planning and design processes lead to increased efficiency.

- Cost-effectiveness allows for budget allocation towards other areas of construction.

Table demonstrating the comparison between custom-sized and standard-sized plywood sheets:

| Aspect | Custom-Sized Sheets | Standard-Sized Sheets |

|---|---|---|

| Availability | Limited supply | Widely available |

| Waste Generation | Higher due to excess material | Minimized due to optimized dimensions |

| Planning & Design | Complex; requires precise measurements | Simplified; follows established standards |

| Cost | Expensive due to customization | Affordable due to mass production |

By employing standardized plywood sizes, builders benefit from streamlined operations while experiencing significant cost savings. Additionally, adhering to industry conventions promotes efficient use of resources and facilitates collaboration among professionals across various stages of construction.

Understanding the benefits of using standard plywood sizes is crucial, but it is equally important to know how to properly cut and install plywood. By mastering these skills, builders can ensure precise construction outcomes that meet their project requirements and expectations.

How to Properly Cut and Install Plywood

Having understood the benefits of using standard plywood sizes, it is essential to learn how to properly cut and install plywood in order to maximize its potential. Let us now explore some key techniques that can help you achieve precise cuts and secure installations.

Example: Imagine you are building a custom bookshelf for your home library. You have carefully measured the space available and purchased a sheet of plywood with the appropriate dimensions. Now, let’s delve into the steps required to effectively cut and install this plywood.

Cutting Techniques:

- Measure Twice, Cut Once: Before making any cuts, double-check your measurements to ensure accuracy.

- Use the Right Tools: Invest in quality cutting tools such as circular saws or table saws equipped with sharp blades suitable for cutting plywood.

- Support Your Material: Place your plywood on a stable surface or use additional supports like sawhorses before starting the cutting process.

- Reduce Splintering: To minimize splintering along the edges when cutting, apply masking tape over the marked line before making your cut.

Installation Tips:

To guide you further, here are some effective installation tips to ensure sturdy placement of your plywood:

| Tips | Benefits | |

|---|---|---|

| 1 | Pre-Drill Holes | Prevents splitting while fastening |

| 2 | Choose Appropriate Screws | Ensures optimal holding power |

| 3 | Maintain Spacing | Allows room for expansion and contraction |

| 4 | Apply Adhesive | Provides added strength and stability |

By following these guidelines, you can enhance both the functionality and aesthetics of your project while minimizing wastage due to poor cutting or improper installation techniques.

Incorporating these best practices will contribute significantly to achieving professional-looking results throughout your woodworking endeavors. With time and practice, you will develop a keen understanding of the intricacies involved in cutting and installing plywood effectively, allowing you to tackle more complex projects with confidence.

Bergmann Lumber

Bergmann Lumber