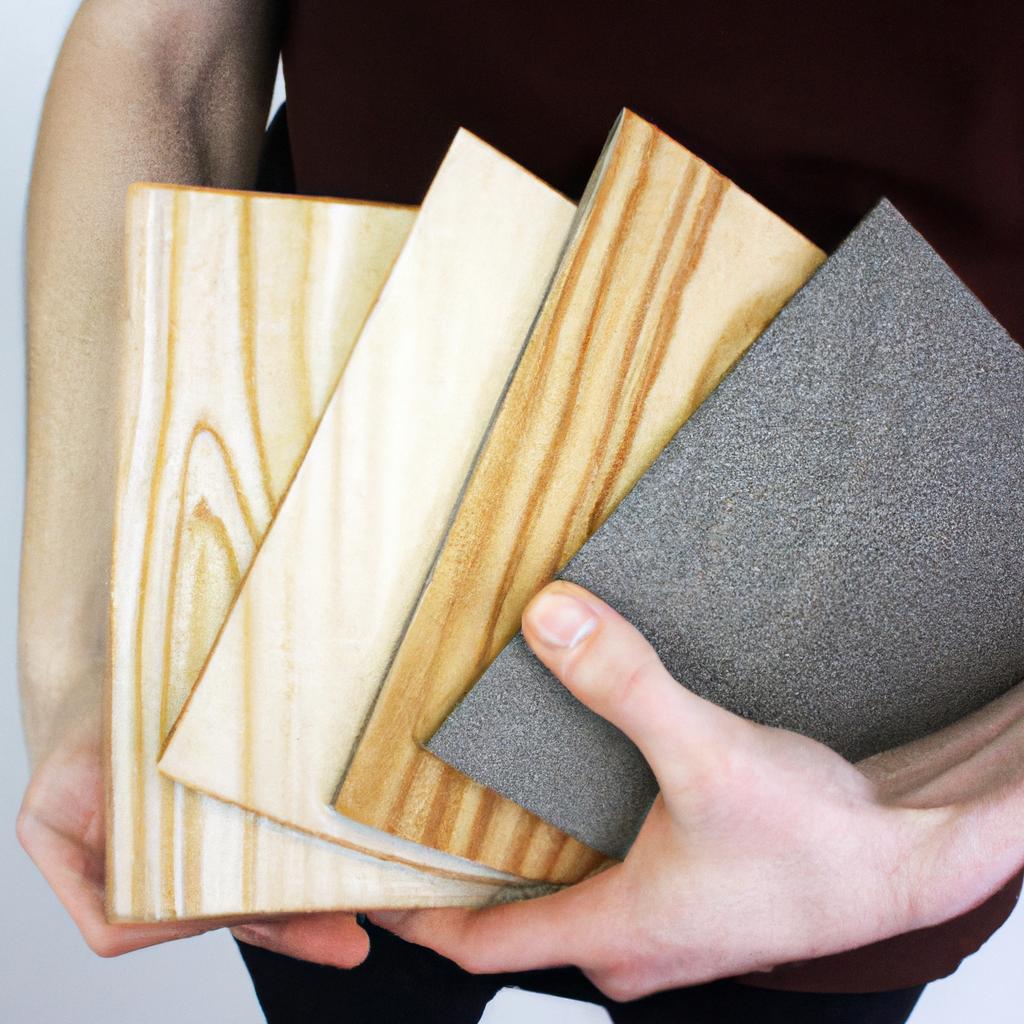

Plywood, a versatile and widely used material in the construction industry, has revolutionized the field of lumber and building materials. Its unique composition and structural integrity make it an ideal choice for various applications, ranging from flooring to roofing and everything in between. Consider, for instance, the case of a hypothetical construction project where plywood is employed as a key component in creating sturdy formwork for casting concrete structures. This article aims to provide readers with an informative guide on the uses of plywood in lumber and building materials, exploring its diverse applications and highlighting its benefits within the context of modern construction practices.

In recent years, there has been an increased recognition of plywood’s significance as a cost-effective alternative to traditional solid wood products. With its laminated layers composed of thin sheets known as veneers, plywood offers enhanced strength, durability, and dimensional stability compared to conventional timber counterparts. The ability of plywood to resist warping or splitting under harsh environmental conditions makes it particularly suitable for exterior applications such as sheathing walls or constructing outdoor furniture. Moreover, due to its engineered structure that distributes weight evenly across multiple layers, plywood provides exceptional load-bearing capabilities when utilized in floor joists or subflooring systems.

Advantages of Plywood over Other Materials

To illustrate the advantages of plywood, let us consider a hypothetical scenario: A construction company is tasked with building a new residential development. The project requires durable and versatile materials that can withstand different weather conditions while also being cost-effective. In this case, plywood emerges as an ideal choice due to its numerous advantages.

Firstly, plywood offers exceptional strength and stability compared to other materials such as solid wood or particle board. This structural integrity makes it suitable for various construction applications, including flooring, walls, roofs, and furniture. Additionally, plywood has a high resistance to warping, cracking, and shrinking when exposed to moisture changes or extreme temperatures.

Secondly, plywood is highly versatile in terms of design possibilities. Its composite nature allows manufacturers to produce sheets in different sizes and thicknesses according to specific project requirements. Moreover, plywood’s uniformity ensures consistent quality throughout each sheet, enabling builders to create precise dimensions and smooth finishes.

Thirdly, one cannot overlook the environmental benefits of using plywood. As a sustainable material derived from renewable sources like trees, proper forest management practices ensure responsible harvesting without depleting natural resources excessively. Furthermore, the manufacturing process produces less waste compared to alternative options such as concrete or steel.

Lastly, the affordability of plywood makes it an attractive choice for both small-scale projects and large-scale constructions alike. With its competitive pricing relative to other building materials on the market today, using plywood can help reduce overall project costs significantly.

In summary,

- Plywood provides exceptional strength and stability.

- It offers versatility in design possibilities.

- It possesses environmental benefits through sustainable sourcing.

- It presents an affordable option for construction projects.

By considering these advantages of plywood over other materials within the lumber industry (as highlighted above), we are now better equipped to explore its common applications in construction projects.

Common Applications of Plywood in Construction

When it comes to selecting materials for construction projects, plywood offers several advantages that make it a popular choice in the industry. One case study that exemplifies these benefits is the renovation of an old house into a modern office space. The project required structural modifications and interior design elements, which were efficiently achieved using plywood. This example highlights how plywood’s unique properties contribute to its widespread use in various applications.

Firstly, plywood exhibits exceptional strength and durability compared to other building materials. Its layered composition consisting of multiple thin sheets of wood glued together creates a strong and stable product. This allows plywood to withstand heavy loads and resist warping or shrinking caused by changes in temperature and humidity. For instance, during the renovation mentioned earlier, plywood was used as subflooring due to its ability to provide excellent support underfoot while maintaining dimensional stability.

Secondly, plywood offers versatility in terms of size and shape. It can be easily cut into different dimensions, making it suitable for customized construction needs. Whether it is creating intricate designs for furniture pieces or constructing large-scale structures like formwork for concrete pouring, plywood proves itself adaptable to varying requirements. In our case study, contractors utilized this characteristic when fabricating bespoke cabinetry and partitions within the renovated office space.

Thirdly, plywood demonstrates cost-effectiveness without compromising quality. Compared to solid wood or alternative engineered products, such as medium-density fiberboard (MDF), plywood provides an affordable option while still delivering reliable performance. This affordability makes it accessible for both small-scale DIY projects and extensive commercial developments alike.

To further emphasize the practicality of using plywood in construction, consider the following emotional bullet points:

- Plywood’s strength ensures long-lasting structures.

- Customizable sizes allow flexibility in design choices.

- Cost-effective nature saves money without sacrificing quality.

- Versatility caters to diverse application requirements.

In addition to these advantages, let us explore some specific applications of plywood in the construction industry through a three-column, four-row table:

| Application | Benefits | Example Use |

|---|---|---|

| Flooring | Durability and ease of installation | Subflooring for offices |

| Cabinetry | Customizability and strength | Kitchen cabinets in residential homes |

| Formwork | Reusability and stability | Concrete pouring on large-scale projects |

| Roof Sheathing | Water resistance and structural support | Residential roofing installations |

With its remarkable features and numerous benefits, it is clear why plywood has become an indispensable material in construction. By understanding these variations, one can make informed decisions when selecting the most suitable type of plywood for a particular project.

Transitioning into the subsequent section about “Different Types of Plywood and Their Uses,” we delve deeper into the diverse range of options available within this versatile material.

Different Types of Plywood and Their Uses

Having explored the common applications of plywood in construction, we will now delve into the different types of plywood and their specific uses. Understanding these variations is crucial for determining which type of plywood best suits a particular project.

Different Types of Plywood and Their Uses:

To illustrate the practical application of various plywood types, let’s consider the example of constructing a small shed. In this hypothetical case study, we need to select suitable plywood for different components such as flooring, walls, roofing, and exterior sheathing. Each of these areas requires distinct characteristics from the chosen plywood.

- Flooring:

- Opt for tongue-and-groove (T&G) or T&G Sturd-I-Floor panels that provide excellent structural stability.

- These panels have interlocking edges that enhance strength while maintaining an even surface for walking on.

- By using such high-quality materials, you can ensure durability and longevity in your shed’s flooring system.

- Walls:

- Choose standard interior-grade plywood with smooth surfaces for wall paneling.

- This type typically has fewer voids and knots, ensuring a cleaner finish once painted or stained.

- Using this grade helps achieve an aesthetically pleasing appearance while providing sufficient support to hold fixtures or shelves securely.

- Roofing:

- Consider selecting roof decking-grade plywood designed specifically to withstand weather elements like rain, snow, and heat exposure.

- Such plywood often comes treated with preservatives to resist mold growth or decay caused by moisture infiltration.

- Its strength contributes to the overall integrity of the roof structure while offering protection against external factors.

- Exterior Sheathing:

- Employ exterior-grade CDX (C-D Exposure) plywood for sheathing purposes.

- This type possesses a high level of resistance to moisture and provides reliable protection against the elements.

- The durable nature of exterior-grade plywood helps safeguard the shed’s structural components from water damage.

Table: Benefits of Plywood in Construction

| Benefits | Examples |

|---|---|

| Strength | Superior load-bearing capacity for flooring systems |

| Durability | Withstands harsh weather conditions on roofs |

| Versatility | Suitable for various applications, including wall paneling |

| Moisture Resistance | Protects structures from potential water damage |

Understanding the different types of plywood and their specific uses allows us to make informed decisions about which variety is best suited for particular construction needs. In the subsequent section, we will explore how plywood serves as a sustainable building material, considering its environmentally friendly attributes.

Plywood as a Sustainable Building Material

Section H2: Different Types of Plywood and Their Uses

In the previous section, we explored the various types of plywood available in the market and their specific applications. Now, let us delve deeper into how plywood is contributing to sustainable building practices.

Imagine a construction project aiming to achieve both durability and environmental consciousness. By incorporating plywood as a key building material, this vision becomes attainable. Plywood not only offers strength and versatility but also serves as an eco-friendly alternative to traditional solid wood panels.

To better understand the benefits of using plywood in sustainable construction, consider the following:

-

Reduced Environmental Impact:

- Plywood is made from thin layers of wood veneer that are bonded together with adhesive.

- This manufacturing process significantly reduces waste compared to solid wood products.

- Additionally, many manufacturers use sustainably sourced timber for plywood production, ensuring responsible forest management.

-

Energy Efficiency:

- The composition of plywood provides insulation properties that can improve energy efficiency within buildings.

- Its thermal resistance helps regulate indoor temperatures by reducing heat transfer through walls or roofs.

- As a result, less reliance on heating or cooling systems leads to reduced energy consumption and lower utility bills.

-

Structural Stability:

- Plywood’s cross-laminated design gives it exceptional structural stability even under heavy loads.

- It has excellent resistance against warping, shrinking, or expanding due to changes in temperature or humidity.

- These qualities make it ideal for flooring, roofing, wall sheathing, and other load-bearing applications.

-

Versatile Applications:

| Application | Benefits |

|---|---|

| Interior Design | Plywood can be used for furniture-making, cabinetry, decorative paneling, and creative architectural elements. |

| Exterior Construction | It is suitable for external cladding, decks, fences, and outdoor structures due to its weather-resistant properties. |

| Interior Partitioning | Plywood’s sound insulation capabilities make it an excellent choice for creating quiet and private spaces within buildings. |

In conclusion, plywood is not only a reliable construction material but also aligns with sustainable building practices. Its versatility, strength, and eco-friendly manufacturing process have made it widely embraced in the industry.

Transitioning into the subsequent section about “Factors to Consider when Choosing Plywood,” let us now delve into some crucial aspects that should guide your decision-making process.

Factors to Consider when Choosing Plywood

Plywood is widely recognized as a sustainable building material due to its numerous environmental benefits. For instance, consider the case study of a residential construction project where plywood was used extensively. The use of sustainably sourced plywood in this project not only reduced deforestation but also minimized waste generation during manufacturing and installation processes.

When choosing plywood for your own projects, there are several important factors to consider. First and foremost, it is crucial to assess the intended application of the plywood. Different types and grades of plywood offer varying levels of strength, durability, and resistance to moisture. Secondly, evaluating the sustainability credentials of the plywood supplier should be a priority. Look for certifications such as Forest Stewardship Council (FSC) or Sustainable Forestry Initiative (SFI), which ensure that the wood used in production comes from responsibly managed forests.

To further emphasize the significance of using sustainable materials like plywood, here are some key points:

- Plywood helps reduce carbon footprint: By opting for sustainably sourced plywood, you actively contribute towards minimizing greenhouse gas emissions associated with deforestation.

- It promotes circular economy: Choosing recycled or reclaimed plywood allows for efficient utilization of resources and reduces waste sent to landfills.

- Plywood supports local economies: Purchasing locally produced plywood supports regional industries and reduces transportation-related emissions.

- It encourages innovation: Continued research and development efforts focus on creating more environmentally friendly alternatives to traditional lumber products.

In addition to these points, let’s take a look at how different properties compare between common types of plywood in terms of strength, durability, ease-of-use, and cost-effectiveness:

| Property | Softwood Plywood | Hardwood Plywood | Marine Grade Plywood |

|---|---|---|---|

| Strength | Medium | High | Very High |

| Durability | Moderate | High | Excellent |

| Ease-of-use | Easy | Moderate | Moderate |

| Cost-effectiveness | Affordable | Expensive | High |

These characteristics can guide you in selecting the most suitable plywood for your specific project requirements.

Transitioning to the subsequent section on proper maintenance and care for plywood, it is important to understand how these practices can extend the lifespan of this sustainable building material. By adopting appropriate measures, such as regular inspections, sealing edges, and protecting against moisture damage, you can ensure that your plywood continues to perform optimally over time without compromising its structural integrity or aesthetic appeal.

Proper Maintenance and Care for Plywood

Having examined the important factors to consider when choosing plywood, it is crucial to understand how proper maintenance and care can significantly enhance its longevity and performance. To illustrate this point, let’s consider a real-life scenario where a construction company utilized plywood panels without adequate care. Over time, due to exposure to moisture and neglecting routine maintenance practices, the plywood panels developed mold and delamination issues. This case study emphasizes the importance of implementing appropriate maintenance measures from the outset.

Proper Maintenance Practices:

- Regular Cleaning:

- Remove dust and debris using a soft brush or vacuum cleaner.

- Wipe down surfaces with a damp cloth or sponge as needed.

- Avoid excessive water usage during cleaning to prevent swelling or warping.

- Preventive Measures:

- Apply waterproof coatings or sealants on exposed edges to protect against moisture damage.

- Use suitable weather-resistant adhesives during installation to minimize water penetration.

- Install gutters and downspouts to divert rainwater away from areas where plywood is used.

- Inspection and Repair:

- Conduct regular inspections for signs of wear, such as cracked veneers or loose layers.

- Promptly repair any damages by replacing affected sections or reinforcing weakened areas.

- Address potential sources of moisture intrusion promptly to prevent further damage.

Taking steps towards proper plywood maintenance not only ensures long-term durability but also offers these benefits:

- Enhanced structural integrity

- Cost savings through reduced replacement needs

- Improved aesthetics in various applications

- Increased safety by minimizing risks associated with deterioration

Emotional Table:

| Benefit | Description |

|---|---|

| Enhanced Durability | Proper maintenance techniques increase the lifespan of plywood, making it more resistant to decay. |

| Cost Savings | Regular upkeep reduces the need for frequent replacements, saving money in the long run. |

| Aesthetic Appeal | Well-maintained plywood surfaces contribute to an overall visually pleasing appearance. |

| Safety | By preventing structural deterioration, maintenance practices ensure a safer environment. |

In summary, considering the case study and understanding the significance of proper care and maintenance, it is evident that neglecting these aspects can lead to severe damage and compromises in plywood performance. Implementing routine cleaning, preventive measures, regular inspections, and timely repairs are essential for maximizing the benefits of using plywood while minimizing potential risks associated with its degradation or failure.

Please let me know if you have any further questions or if there’s anything else I can assist you with!

Bergmann Lumber

Bergmann Lumber